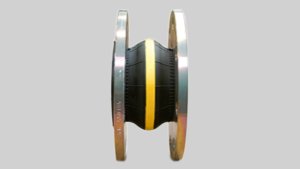

Description

The Proco Style 442-BD Molded Expansion Joints can be used for corrosive applications that are found in industries such as chemical-petrochemical, industrial process piping systems, power generation plants, pulp/paper plants, water and wastewater sewage, and pollution control systems. This expansion joint features two convolutions for minimal movements, higher pressure/temperature ratings, and short face-to-face opening requirements. Wherever metallic joints, lap joints, or PTFE and FEP-lined rubber expansion joints were previously used, the Proco Style 442-BD can also be used.

Some notable features of the Proco Style 442-BD include:

- Absorption of pipe-wall and fluid-borne noise

- Reduction of system stress and strain

- Isolation of mechanical vibration and motion

- Superior “Flex Life” and strength

- Tested force pound and spring rate tables

- Coated flanges and factory set limit bolts

- Chemical service capability at minimal cost

- Elimination of electrolysis

- Protection against start up and surge forces